Home /

Expert Answers /

Mechanical Engineering /

a-chemical-reactor-operates-at-a-high-internal-temperature-of-t-inner-600k-and-is-surrounded-by-a-pa209

(Solved): A chemical reactor operates at a high internal temperature of T_(inner )=600K and is surrounded by a ...

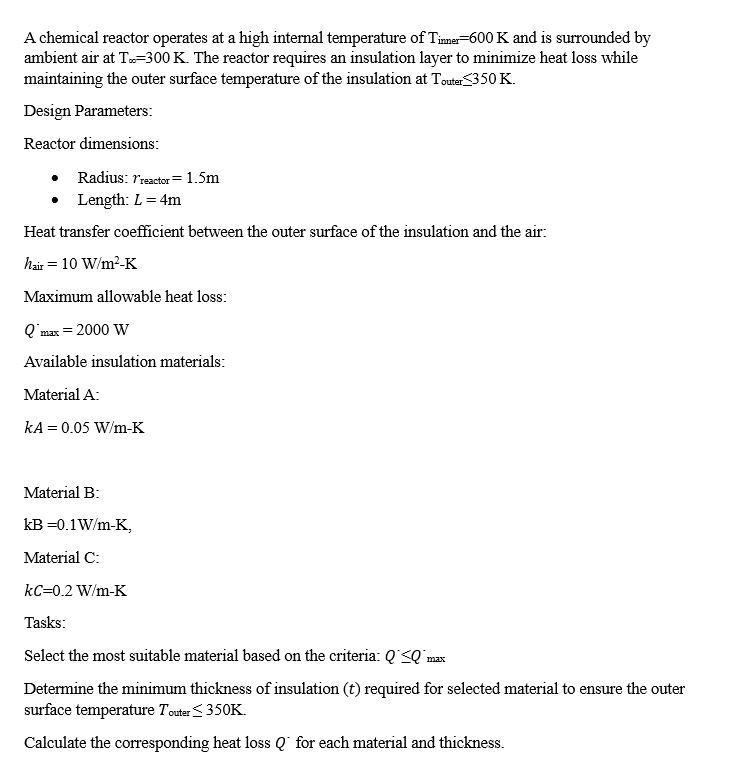

A chemical reactor operates at a high internal temperature of T_(inner )=600K and is surrounded by

ambient air at T_(\infty )=300K. The reactor requires an insulation layer to minimize heat loss while

maintaining the outer surface temperature of the insulation at T_(outer )<=350K.

Design Parameters:

Reactor dimensions:

Radius: r_(reactor )=1.5m

Length: L=4m

Heat transfer coefficient between the outer surface of the insulation and the air:

h_(air)=10(W)/(m^(2))-K

Maximum allowable heat loss:

Q_(max)^(-)=2000W

Available insulation materials:

Material A:

kA=0.05(W)/(m)-K

Material B:

kB=0.1(W)/(m)-K,

Material C:

kC=0.2(W)/(m)-K

Tasks:

Select the most suitable material based on the criteria: Q^(-)<=Q_(max )

Determine the minimum thickness of insulation (t) required for selected material to ensure the outer

surface temperature T_(outer )<=350K.

Calculate the corresponding heat loss Q^(-)for each material and thickness.